Contact us

Want to become a StabiliForce Dealer?

FINANCING AVAILABLE

Why choose hydraulic piles?

Hydraulic piles are more durable, efficient and also achieve better overall results than screw piles.

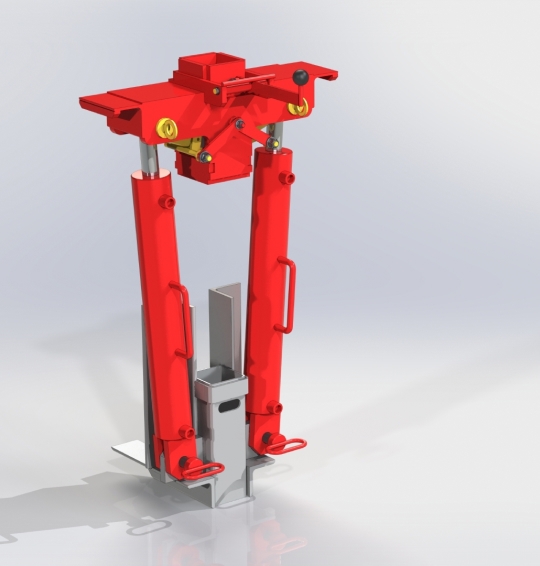

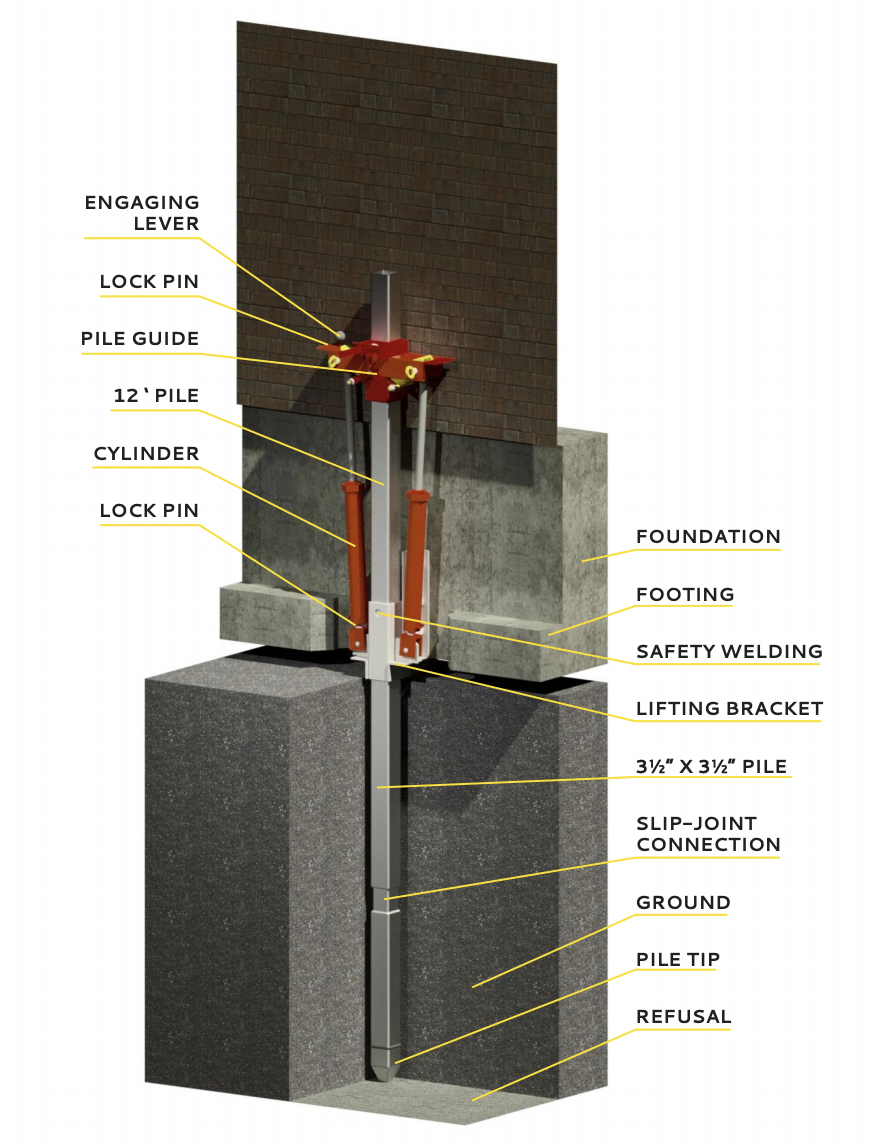

By using this technology we can correct the sag of a building by using its own weight. It’s the only technology that allows the piles to reach the bedrock. Also, these piles take up very little space and emit no vibration. It is, therefore, possible to drive piles both inside and outside of the building. Hydraulic piles support the weight of a building as well as its system of hydraulic cylinders in order to straighten the foundation in part or totally.

Unlike screw piles, hydraulic piles guarantee a building’s stability—they offer the definitive solution for foundation sinking. Our lab-tested foundation chairs can each support up to 80,000 lbs. Come explore the daring side of dependability.

Major differences between hydraulic piles and screw piles:

Hydraulic piles

Screw-in piles

-

Have a load capacity of 40,000 pounds with a safety factor of 2

-

Can reach the rock

-

Support our WSP Certified foundation chairs

-

Are filled with concrete to ensure stability

-

Have a load capacity of 26,000 pounds with a safety factor of 1.5

-

Cannot reach the rock

-

Break up the soil due to screwing during the depression

-

Cannot ensure total stabilisation with all types of soil

-

Can not be filled with concrete.

Our WPS Certified foundation chairs

In addition to being anticorrosive, our foundation chair models meet the highest quality standards set by WSP Global—they’re recognised among the industry’s best.